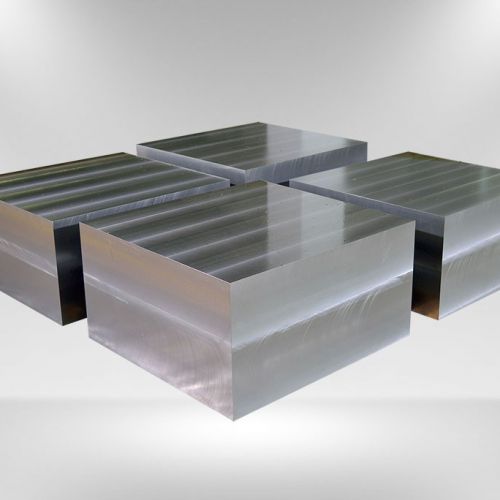

1.2343 ESR

发布时间:2020-10-27 10:09:45

Welcome,Dongguan Oliver Steel Mould Co. LTD

发布时间:2020-10-27 10:09:45

1.2343 ESR

Typical Applications

-Die casting moulds and dies (insert and accessories)

-Extrusion dies and accessories

-Forging tools and inserts

-Light alloys forging and Forming tools

-Hot shears, shrinkfit parts and wear resistance parts

Typical Composition

200BHW ( ESR ) H11 ESRannealled (>Hb200) for improved machinability

CHEMICAL COMPOSITION in %

c | Si | Mn | P | s | Cr | Mo | V |

0.32 | 0.2 | 0.3 | 4.8 | 1.2 | 0.4 | ||

0.38 | 0.5 | 0.5 | 0.010 | 0.003 | 5.2 | 1.4 | 0.6 |

1.2343 esr Enhanced mechanical properties with machiniability and polishability,

good ductility and thermal wear resistance

1.2343 esr H11 ESR Properties

-Good thermal performance hot work steel

-Enhanced ductility even under extreme thermal condition -Enhanced thermal fatigue and wear resistance

-Nitridcable

-Good polishing performance

-Enhanced dimensioal stability

-Homogeneous hardenability

-Homogeneous structure

1.2343 ESR Ultrasonic test acceptable level:E/e, guarantee no defect

All supplies compile with NADCA#207 requirement

Data of heat treatment

Annealled at Delivery

Temperature : 850*0

Gradient: Less than 25℃/h

Hardness: ~Hb180

NADCA recommendations;

Hardening

Gradually heat parts

Pre-heat temperature : 650℃

Quenching temperature : 990℃

Holding time : 120mins

cools down to 150t

Tempering

Temperature about 595℃

Stress Relieve

30-55T lower than last tempering temperature, gradually cools down to 200 and than natural cool in open air