About Oliver steel moldmore》

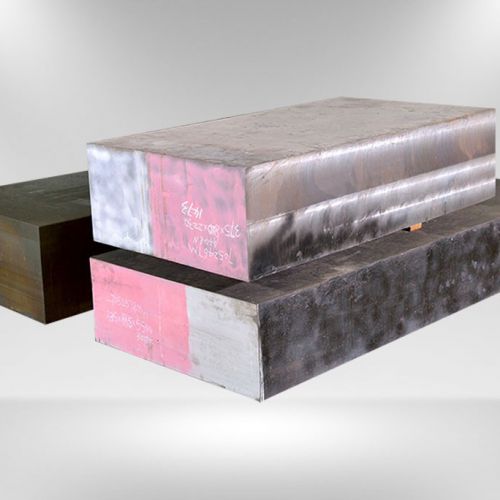

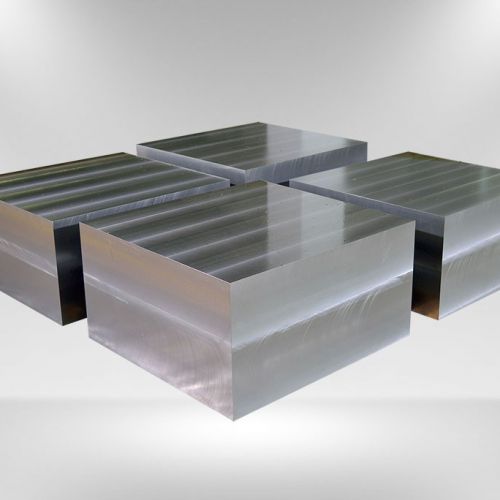

Dongguan Oliver Steel Mould Co Ltd was established in 2009 in Tangxia, Dongguan. It is a professional manufacturer of hot work tool steel, roughing service, CNC roughing and precision processing and heat treatment supporting services. The company covers an area of 15,000 square meters. The company has been engaged in tool steel trading and heat treatment processing industry since 1986, and has thorough understanding of tool steel and processing technology. After years of development, the company has become one of the largest tool steel supply and heat treatment technology supporting service provider in the Pearl River Delta region.

Technical supportmore》

Contact usmore》

86-0769-82022568

86-0769-87928301

Dongguan Oliver Steel Mould Co. LTD

地址:NO.52 Qiaoqing Road, Tangxia Town, Dongguan City

email:oliversteel@vip.163.com / Kenny@oliversteelhk.com