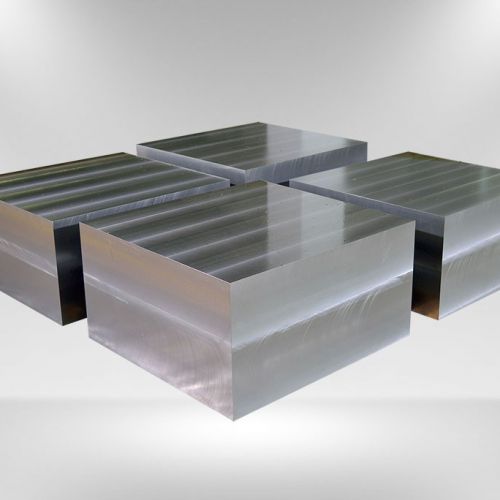

84I8 ESR

发布时间:2020-10-27 09:52:39

Welcome,Dongguan Oliver Steel Mould Co. LTD

发布时间:2020-10-27 09:52:39

84I8ESR CN AISI A348VAR

Typical Applications

-High quality high performance hot work tool steel

-For big size moulds and dies for die casting of

-Alumium and Magnesium alloys, inserts, slides;

-Aluminium extrusion tools, liners, pressure pads

-Holders and mandrels; Forging dies.

Typical Composition (in %) and requirements

HB 180 AISI A348VAR annealled (>Hb180) formachinability

CHEMICAL COMPOSITION in %

c Si Mn p s Cr Mo V

0.32 0.10 0.35 ≤0.010 5.20 2.20 0.50

0.38 0.30 0.65 ≤0.003 5.40 2.40 0.65

8418ESR CN High performance hot work tool steel with enhanced mechanical properties, especially at

high temperature, good ductility and high tempering resistance, superb toughness and thermal fatigue resistance perfect for die casting, forging and extrusion applications

AISI A348VAR Properties

-high thermal fatigue and cracking resistance -high thermal wear resistance

-good ductility

-good tempering resistance

-homogeneous thermal hardenability

dimension stability and coating options

Ultrasonic test acceptable level:E/e, guarantee no defect

All supplies in compliance with NADCA#207 requirement

Data of heat treatment

Annealled at Delivery

Temperature : 850X1

Gradient: Less than 25℃/h

Hardness: Hb200

NADCA recommendations:

Hardening

Gradually heat parts

Pre-heat temperature : 850℃

Quenching temperature : 1025℃

Holding time : 120mins

cools down to 150*C

Tempering

Temperature about 580~600℃

Stress Relieve

25-45T lower than last tempering temperature, gradually cools down to 200 and than natural cool in open air.